Though there’s been a change in company rights that’s resulted in a shift in priorities or a drive to reduce costs? Perhaps your sales are rocketing and your in-house abilities are at complete ability? Or you just want more time to focus your attention on other features of your business?

Whatever your reasons for selecting to outsource, it’s significant to know that any transform in the process takes time and needs careful deliberation.

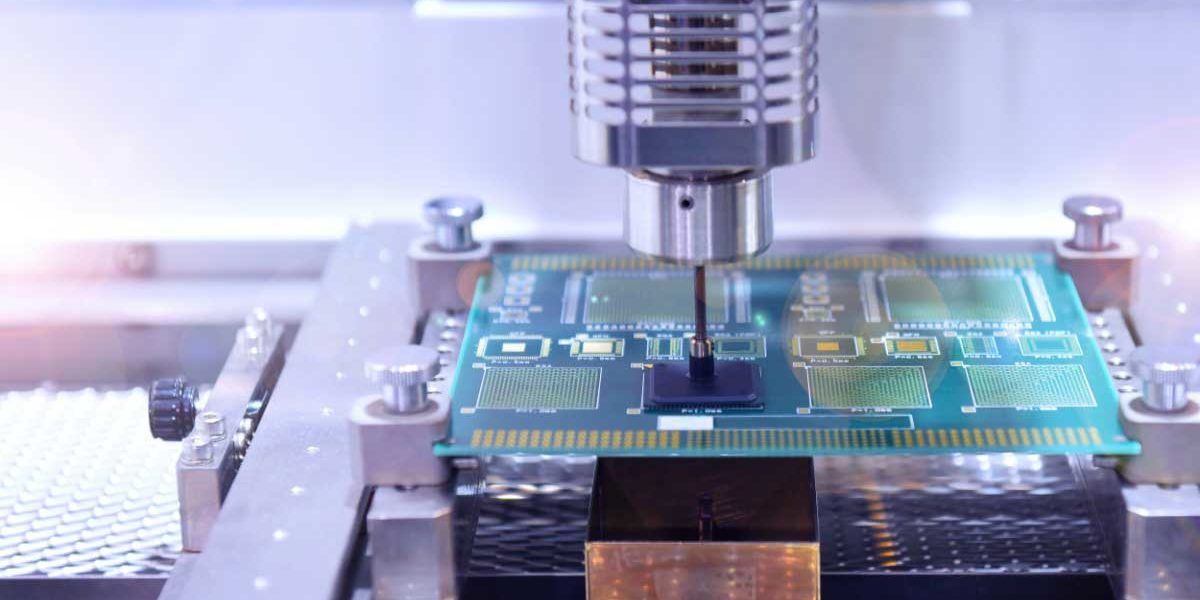

In the below post, we discover tips that will guide you through the process of shortlisting, identifying auditing and choosing your Electronics Manufacturing Services.

Set up your team

The primary phase in the development will be to put together a team of experts who will take accountability for the navigation of the project. Perfectly plan for as wide a range of skills as you perhaps can – engaging input from engineering, quality, procurement, and manufacturing.

You’ll want to allot a project leader who can generate the plan and observe the project from start to finish. Connecting HR can also be vastly expensive, and particularly if you’re planned outsourcing approach is likely to result in changing roles or changes to personnel numbers.

Base on the compassion of your project, it may also be worth getting the components of the team to sign a non-disclosure agreement to make sure entire privacy.

Set your objectives

It’s vital to place clear goals before you start the process of shortlisting candidates. Do you want to transfer just one element of your function for instance? Or do you believe a whole, end-to-end, outsourcing organization?

Reaching a final decision on the proper supplier can take time, so it’s essential to stay mindful of your unique purposes throughout the development and to make specific, reachable and assessable milestones so you can plan your development.

You may also discover it supportive to start drafting your Terms and Conditions (T&Cs) at this early phase so you can set up and describe the criteria for your prospective providers.

Start your search

Your search for a PCB Design Services strength primarily begins with a long list of 10 or so applicants – but preferably, you’ll look to find this down to the three or four that you consider could provide the best prospective robust for your business.

While online research can be useful, it can also be vastly time-consuming as you shape your way through the alternatives. If in uncertainty you may well discover that the tried-and-tested approach of suggestion or word of mouth is positive for serving to recognize your views.

During this first search phase, it can be helpful to maintain a few clear objectives in mind. Perhaps you’re after an EMS partner that is located near to your own operation? Or maybe you’d prefer a supplier who has multiple locations throughout the UK or that has manufacturing facilities abroad?

Quiz your candidates

A pre-qualifying survey can be a priceless next step in serving you decides the prospective fit between you and your prospective EMS partner and to decrease your shortlist down to the last two or three candidates.

Their promise to the business connection is going to be key. Look for signs that they’re authentically involved in you and your business and that they can show that they have the skills and knowledge to express your products.

Plan a site visit

Once you’ve recognized your final choice, the next sound phase will be to place a tour of your forecast’ manufacturing amenities.

Taking the prospect to view the business first-hand can offer an essential first notion of the company and its civilization.

It’s also a possibility to place faces to names, to ask them additional about their abilities and to verify that the people you’re discussing to are the real decision-makers who will be navigation your project from beginning to end.

Submit your RFQ

Your RFQ (Request for Quotation) will offer your provider with all the key business and technical information that they’ll require to offer you a perfect quotation.

From a profitable viewpoint, it’s expected to consist of predictable annual practice figures for your products, a sign of capacity and the expected occurrence of orders.

From a technical viewpoint, you’re expected to require offering a major amount of data as well as a Bill of Materials (BOM), parts drawings, fabrication make packs, and manufacturing/test data.

Review their functions

A review of your potential EMS partner’s functions will predictably involve numerous elements. During the site audit, you can interact with the people who will be in charge of the manufacture of your product.

It’s also costly to achieve a quality audit of their developments and calculates to ensure they have an obvious formation in place and that they can explain the safe and imaginative management of your make data. If your sales tend to be standard or are subject to peaks in a movement then you’ll also want to ensure that they can manage with the amazing.

Once you’ve finished all your quality checks and have expected all the information back from the RFQs the final phase in your selection method will be to reconvene your team, evaluate the pros and cons of each contestant and make your final decision.

Bottom Line

Choosing for Product Development Services to an EMS provider requires proper planning and consideration. And still, once you’ve made your choice there may still be stuff that analysis you or that doesn’t go relatively to sketch.

A skilled EMS partner has been there before. They know the challenges and they’ll be bright to keep you through the development to ensure you achieve the objectives that you’re after.