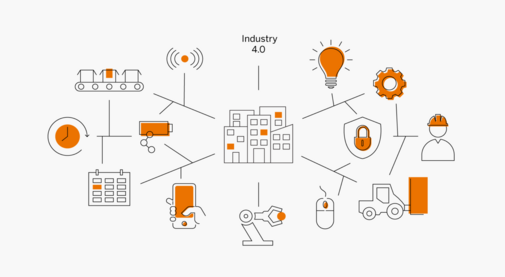

What is industry 4.0?

Industries benefitted from scientific progress at times. When science and technology brought a dramatic about-face in industrial history, it was called the first industrial revolution. Significant discoveries in physics and chemistry and inventions of then-revolutionary machines initiated it. Machines driven by the force of vapor and hydraulic power were the main factors behind it. After that, electricity manipulation made mass production possible, and machines started replacing workers in the second revolution. The third industrial is said to have with the advent of computers and the internet, and it has opened the doors for the fourth industrial revolution. The fourth revolution in industries, aka Industry 4.0, is continuing the procedure of its predecessor – growing the involvement of machines and software in commerce.

We’re talking about Industry 4.0. Computerization and digitization had pushed the commercial field to new frontiers. Now, the fourth revolution sees computers, software, and sensory devices combining to improve quality. For instance, sensors will collect data, and computers will process that data, and provide genuine feedback. Moreover, the information will be decentralized. So, one can easily access the essential information. The involvement of computers and AI will improve the quality of products. As a result, manufacturers will grow customer satisfaction. Likewise, employers will increase employee satisfaction with automated payroll and performance management.

What Areas Has Industry 4.0 Touched?

Industry 4.0 has brought about a never before transformation. No area in commerce remains untouched from this revolution. However, we have elaborated on some significant domains that have been touched by Industry 4.0 further in this article.

-

Manufacturing Process:

Probably, manufacturing gets more advantages than any other domain in the industrial sector. In factories, sensory devices will monitor the conditions and forecast any accidents caused by the faults in the machines. Moreover, according to designs made in computers, connected manufacturing units will automatically shape various things. As a result, we can manufacture goods in less time.

-

Quality Check:

Business owners can use proper monitoring facilities and get great results. Computers accurately monitor the products’ measurements according to the pre-defined criteria and derive odd products. The margin of error in checking will remain lower than traditional manual checking. Automated facilities can check the quality of goods on a large scale in less time which can be impossible with human effort.

-

Transportation:

Transportation is one of the essential aspects of the industrial field. This aspect will see a novel change because of technological progress in automobiles. Modern technology has already empowered us to make automated vehicles. Moreover, computers will predict changes in weather and conclude if weather is suitable for transportation. Latest monitoring strategies such as implementing MDM-enabled GPS tracking and Geo-fencing will help businesses locate and monitor their moving shipments in real time.

-

Payroll:

The payroll process is an essential component of HR management. However, employers, business owners, or HR managers used to face great difficulties in the manual procedure, be it calculating wages, keeping a record of employees’ borrowings, or taking care of laws. This scenario has started to vanish with the advent of automated payroll solutions. Such software can easily calculate salaries, track employees’ advances, and keep the payroll lawfully compliant.

Significance Of Payroll Automation In Industry 4.0:

Industry 4.0 is a holistic transition, covering all the domains related to industries. And the payroll process is not an exemption in it. Payroll is a vital task for employers and HR staff as it directly affects employees’ satisfaction. Any inaccuracies occurring in this process will result in unhappiness among workers. But, the sigh of relief for the business owners and HR professionals is that they can deploy web-based payroll software. Such software can resolve all the worries associated with payroll. Here we have mentioned some notable changes payroll software brings in industries.

-

Accurate Calculations:

Payroll software handles all the calculations of the process efficiently. For example, it calculated salaries with pre-designed shifts and deduction formulas. As a result, managers can get rid of tedious calculations and save time.

-

Instant Salary Process:

Earlier, cash payments and paycheques were accepted modes of salary payments. However, with significant progress on the internet in the past few years, online fund transfer has been the latest and most popular salary payment method in companies. Payroll software enables managers to process salaries with a single click.

-

Legal Compliance:

Companies have to follow various rules and regulations implemented by the government. Therefore, manually handling the process may raise some chances of errors and legal penalties. But, an automated payroll solution ensures a lawful payroll process and avoids any legal issues.

Conclusion:

Industries have benefited from scientific advancements for many years. Computers, devices, and software have united in modern technology. We can leverage the latest technology to automate many functions of industries. Industry 4.0 is all about the intervention of machines and AI in various stages of business.